Printing plate roller applications: Enhancing Printing Efficiency

Printing plate rollers are critical components of printing machines, serving as the interconnection between the plate cylinder and the printing blanket. They apply ink or other specialty fluids to the printing plate surface, ensuring high-quality print output. As such, printing plate roller applications play a critical role in determining the efficiency, productivity, and output quality of various printing processes. Here's a closer look at some of the primary applications of printing plate rollers:

Offset Printing

Offset printing is a widely used printing technique that involves transferring an inked image from a plate to a rubber blanket, and then onto paper or another printing substrate. Printing plate rollers facilitate this process by applying ink to the printing plate surface, ensuring uniformity and consistency of the ink layer. Additionally, printing plate rollers smooth out any surface irregularities or imperfections that might result in uneven ink transfer or blurred images.

Letterpress Printing

Letterpress printing is a traditional type of printing that involves pressing a raised or engraved image onto paper or another substrate. Letterpress printing plate rollers play a crucial role in this process by applying the necessary force to transfer the image onto the substrate. Additionally, printing plate rollers help in inking the images correctly, ensuring optimal color rendering and print quality.

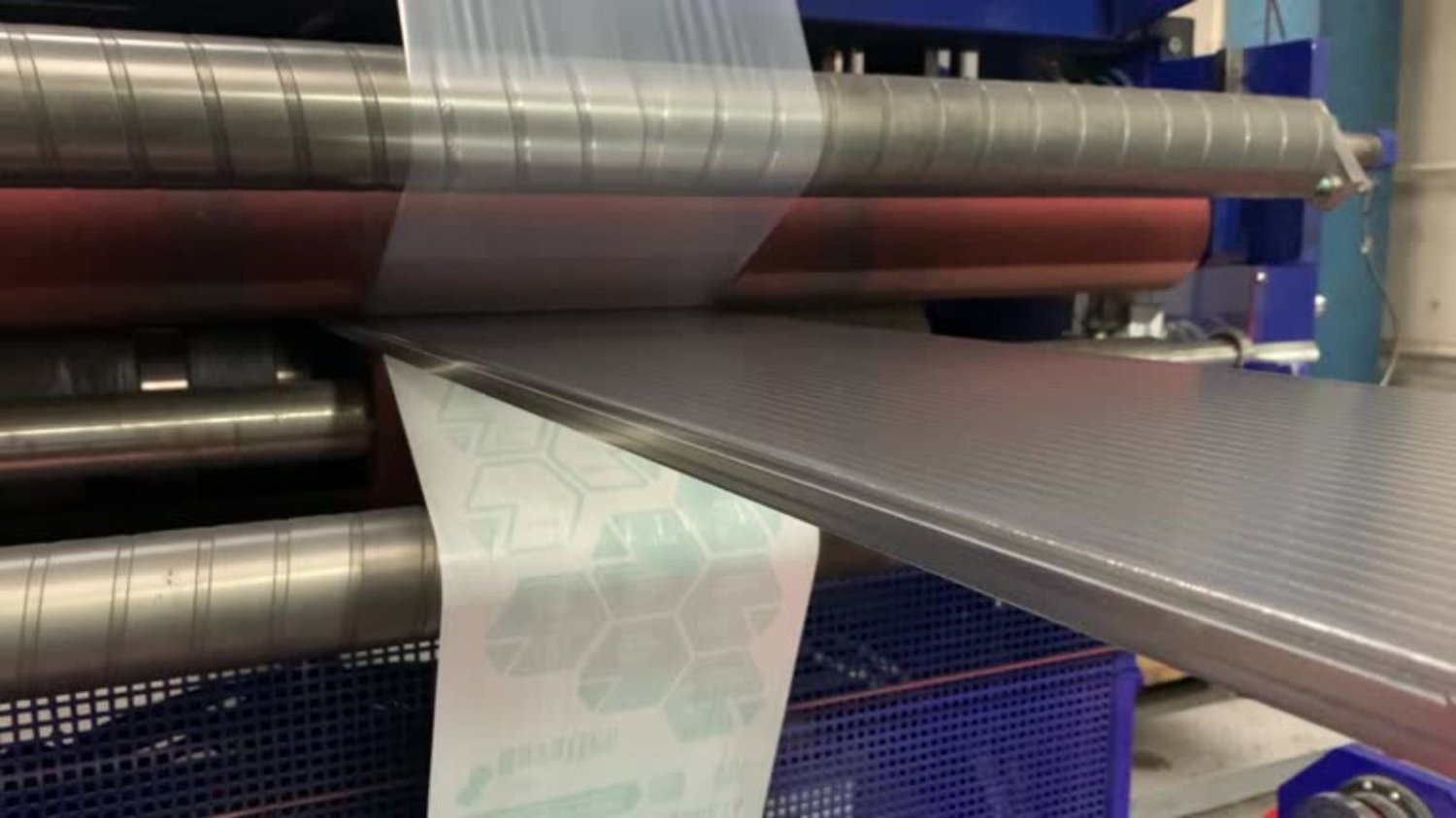

Flexographic Printing

Flexographic printing, also known as flexo printing, is a form of relief printing that uses flexible printing plates and a rotating flexible printing plate roller. Flexographic printing plate rollers are used to apply ink to the printing plate surface while also ensuring proper alignment between the printing plate and the substrate. Flexographic printing plate rollers are essential to ensure high-quality, stable printing output without any issues of smearing or blurred images.

Gravure Printing

Gravure printing is a high-volume printing technique that relies on engraved cylinders to print images onto various substrates. Printing plate rollers are used to apply and distribute the ink evenly onto the engraved cylinders, ensuring high-quality images and a smooth printing process. Additionally, printing plate rollers play a crucial role in maintaining the proper clearance between the engraved cylinders, which is necessary for consistent and reliable printing output.

Digital Printing

Digital printing is a rapidly growing area of printing that uses digital files to produce high-quality printed products. Printing plate rollers used in digital printing apply a liquid toner or ink to the printing plate surface, ensuring optimal image and ink adhesion. Digital printing plate rollers are critical in ensuring tight registration and accurate print output.

Label Printing

Label printing is a specialized type of printing that involves the production of pre-printed labels or stickers. Printing plate rollers play a critical role in label printing as they help to apply ink to the printing plate surface uniformly, ensuring high quality and consistent print output. Additionally, printing plate rollers are crucial for ensuring that the labels are printed accurately, with no registration issues and minimal wastage.

Flexible Packaging

Printing plate rollers are widely used in the flexible packaging industry, where they are critical in producing high-quality, attractive, and functional packaging materials. Printing plate rollers are used to apply and distribute ink onto the printing plate surface while ensuring optimal accuracy and registration. Additionally, printing plate rollers play a crucial role in determining the film-to-plate clearance, which is essential in producing consistent and reliable printing output.

Metal Decoration

Printing plate rollers are essential in the metal decoration industry, where they are used to apply and distribute ink or other specialty fluids onto the metal surface uniformly. Printing plate rollers are used to fix the design onto the metal surface with high precision and consistency. Additionally, printing plate rollers help to smooth out any surface imperfections or in-balance that may affect the quality of the final printed images.

Decorative Printing

Decorative printing involves the production of high-quality, visually appealing prints that can be used in a wide range of applications, from signage and murals to textiles and wallpapers. Printing plate rollers are critical in decorative printing as they help to apply ink to the printing plate surface smoothly and uniformly, ensuring optimal image and color rendering. Additionally, decorative printing plate rollers are designed to deliver high-quality prints with high resolution and clarity.

Security Printing

Security printing is a specialized type of printing that involves producing high-security or tamper-evident prints, such as banknotes, passports, and identity cards. Printing plate rollers are critical in security printing as they help to apply ink or other specialty fluids with high precision and consistency, ensuring optimal security features and protection against counterfeiters. Security printing plate rollers are designed to deliver high-quality prints with advanced security features such as microprinting, guilloches, and holographic images.