Welcome to the World of Precision roller manufacturing

In the world of manufacturing, precision is key. From automotive to aerospace industries, precision roller manufacturing plays a crucial role in ensuring the smooth operation of various machinery and equipment. In this article, we will delve into the intricacies of precision roller manufacturing, exploring its importance, applications, and the processes involved. So, let's dive right in!

The Significance of Precision Roller Manufacturing

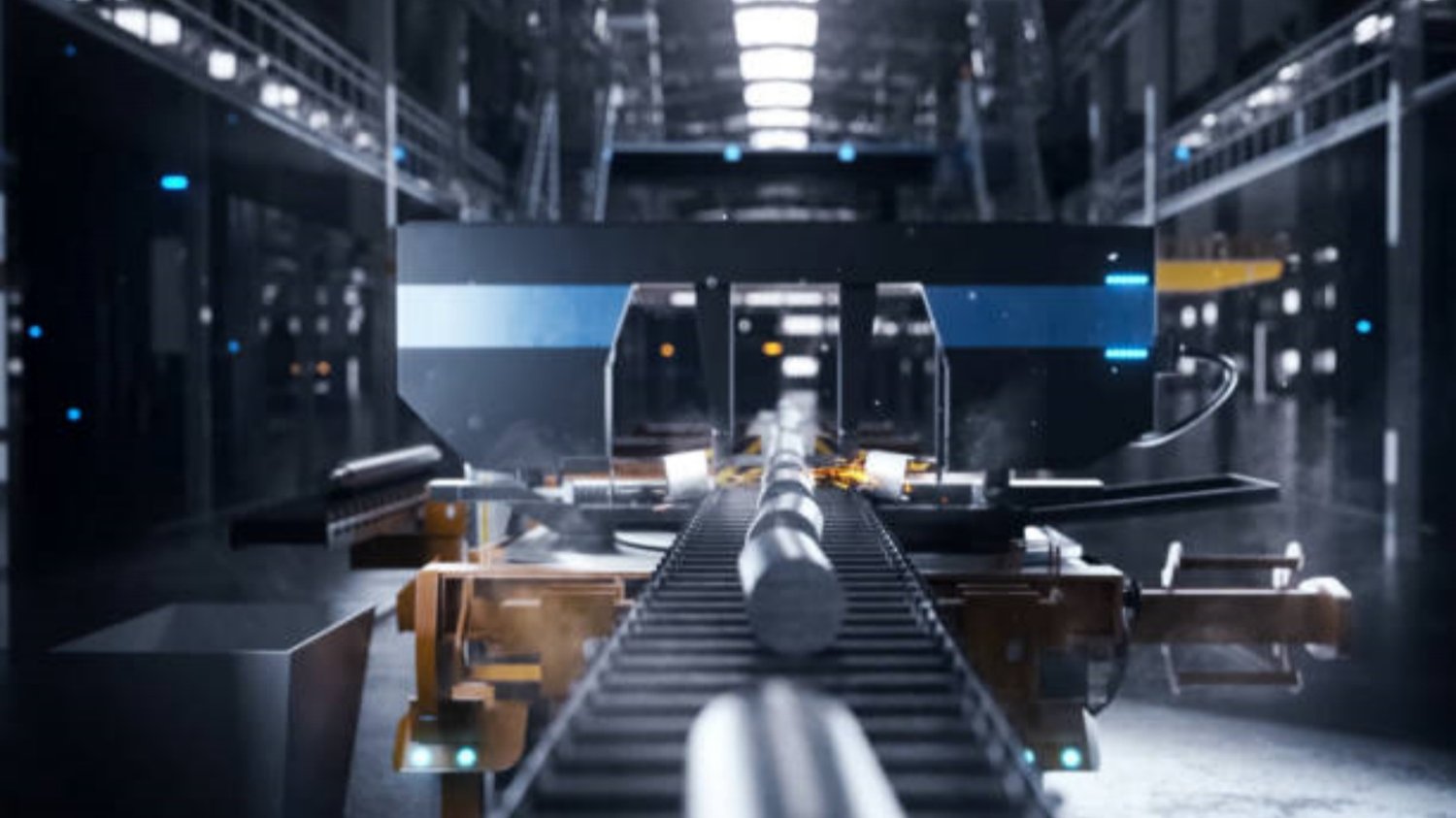

Precision roller manufacturing is the process of creating high-quality rollers with precise dimensions and tolerances. These rollers are utilized in a wide range of applications, including printing, packaging, material handling, and more. The significance of precision roller manufacturing lies in its ability to enhance the efficiency, reliability, and performance of machinery and equipment.

Whether it's a conveyor belt system in a manufacturing plant or a printer in a publishing house, precision rollers ensure smooth movement and accurate alignment of materials. The precise dimensions and uniform surface finish of these rollers contribute to reduced friction, minimized wear and tear, and enhanced overall performance.

The Process of Precision Roller Manufacturing

The process of precision roller manufacturing involves several steps, each crucial for achieving the desired quality and precision. Let's explore these steps in detail:

1. Design and Engineering

Before the manufacturing process can begin, a thorough understanding of the application and requirements is essential. Design and engineering teams work together to create detailed plans, considering factors such as load capacity, material compatibility, and environmental conditions. Advanced CAD software is often utilized to develop precise 3D models.

2. Material Selection

The choice of material for precision rollers depends on the specific application and its requirements. Common materials used include stainless steel, aluminum, and various types of plastics. Factors such as corrosion resistance, hardness, and thermal stability are taken into account during material selection.

3. Machining and Fabrication

Once the design and material selection are finalized, the manufacturing process moves to machining and fabrication. Precision machining techniques, such as CNC milling and turning, are employed to shape the rollers according to the design specifications. Fabrication processes, such as welding or adhesive bonding, may also be involved, depending on the roller's construction.

4. Surface Treatment

To ensure optimal performance and longevity, precision rollers undergo surface treatment processes. These processes can include grinding, polishing, or coating, depending on the specific requirements. Surface treatment enhances the roller's durability, reduces friction, and improves its resistance to wear and tear.

5. Quality Control

Quality control is an integral part of precision roller manufacturing. Advanced inspection techniques, such as coordinate measuring machines (CMM), are used to verify the dimensional accuracy and tolerances of the rollers. Additional tests, such as hardness testing and surface roughness analysis, may also be performed to ensure the rollers meet the required specifications.

Applications of Precision Roller Manufacturing

Precision rollers find applications in various industries and sectors. Let's explore some of the key areas where precision roller manufacturing plays a crucial role:

1. Printing Industry

In the printing industry, precision rollers are utilized in printing presses to ensure accurate ink distribution and paper feeding. These rollers enable smooth movement and precise alignment of paper, resulting in high-quality prints and efficient operation.

2. Packaging Industry

Precision rollers are essential in the packaging industry, where they facilitate the smooth movement of conveyor belts, ensuring precise positioning and alignment of packages. From food packaging to pharmaceutical packaging, precision rollers contribute to efficient production and reduced downtime.

3. Material Handling

In material handling applications, precision rollers are used in conveyor systems to transport goods smoothly and efficiently. These rollers minimize friction, enabling the seamless movement of materials, whether it's in a warehouse or a manufacturing plant.

4. Industrial Machinery

Industrial machinery, such as printing machines, laminators, and extruders, rely on precision rollers for their precise operation. These rollers contribute to the accurate movement and alignment of materials, ensuring consistent and high-quality output.

5. Automotive Industry

Precision rollers play a crucial role in the automotive industry, where they are used in various applications, including engine components, transmission systems, and steering mechanisms. These rollers ensure smooth operation and precise alignment, contributing to the overall performance and reliability of vehicles.

The Future of Precision Roller Manufacturing

As technology continues to advance, so does the field of precision roller manufacturing. New materials, such as composites and advanced polymers, are being explored for their unique properties and benefits. Furthermore, advancements in automation and robotics are revolutionizing the manufacturing processes, enabling higher precision and efficiency.

In conclusion, precision roller manufacturing is a critical aspect of modern manufacturing industries. From improving efficiency and reliability to enhancing product quality, precision rollers play a vital role in various applications. As the demand for high-performance machinery and equipment increases, the importance of precision roller manufacturing will only continue to grow.