Introduction

Efficient cigarette filter paper production is a crucial aspect of the tobacco industry. The production process involves the creation of high-quality filter papers that effectively remove harmful substances from cigarette smoke. This article explores various aspects of efficient cigarette filter paper production, including raw materials, manufacturing techniques, quality control measures, and environmental sustainability. By understanding these factors, manufacturers can enhance the quality of their filter papers while minimizing their impact on the environment.

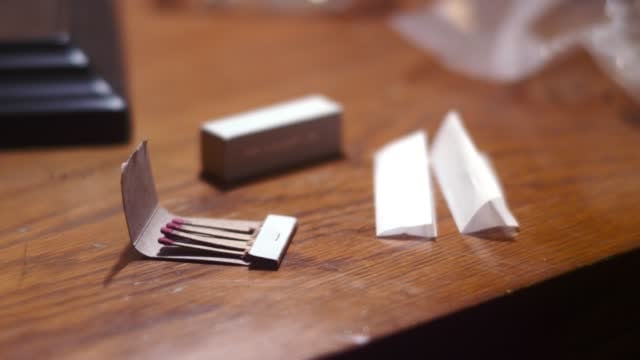

Raw Materials for Filter Paper Production

Efficient cigarette filter paper production begins with the careful selection of raw materials. The primary material used in filter paper production is cellulose fibers derived from wood pulp. These fibers are chosen for their ability to trap particulate matter and remove harmful chemicals from cigarette smoke. Additionally, manufacturers may incorporate other materials, such as activated carbon or flavor enhancers, to enhance the filtering properties or taste of the filter paper.

Manufacturing Techniques

The manufacturing techniques employed in efficient cigarette filter paper production play a significant role in determining the quality of the final product. One common technique is the wet-laid process, which involves the formation of a fibrous mat from a water suspension of cellulose fibers. This mat is then pressed, dried, and cut into individual filter segments. Another technique is the air-laid process, which utilizes air instead of water to form the fibrous mat. This technique offers advantages such as increased porosity and improved uniformity.

Quality Control Measures

To ensure the production of efficient cigarette filter papers, manufacturers implement rigorous quality control measures. These measures involve testing the filter papers for various parameters, including air permeability, pressure drop, and efficiency in removing harmful substances. Advanced testing equipment and statistical analysis are employed to assess the quality of the filter papers, allowing manufacturers to make necessary adjustments and improvements to their production processes.

Enhancing Filter Paper Efficiency

Efficiency is a key factor in efficient cigarette filter paper production. Manufacturers continually strive to enhance the filtration efficiency of their filter papers to reduce the intake of harmful substances by smokers. This is achieved through the optimization of fiber density, pore size distribution, and the incorporation of specialized additives. Research and development efforts focus on identifying innovative materials and technologies that can further enhance the filtration efficiency of cigarette filter papers.

Sustainability in Filter Paper Production

As the demand for sustainable products grows, manufacturers are increasingly focused on implementing environmentally friendly practices in cigarette filter paper production. This includes sourcing raw materials from responsibly managed forests, reducing water and energy consumption during manufacturing processes, and implementing recycling programs for waste materials. By adopting sustainable practices, manufacturers can contribute to the preservation of natural resources and minimize their ecological footprint.

Advancements in Filter Paper Technology

Advancements in technology have played a significant role in the evolution of efficient cigarette filter paper production. Nanotechnology, for example, has enabled the development of nanofiber-based filter papers with enhanced filtration properties. These nanofibers have a high surface area-to-volume ratio, allowing for efficient trapping of fine particles and harmful chemicals. Additionally, advancements in additive technology have led to the incorporation of specialized materials that can selectively remove specific compounds from cigarette smoke.

The Role of Automation

Automation has revolutionized the production process of efficient cigarette filter papers, leading to increased productivity and quality. Automated systems can precisely control various parameters, such as fiber dispersion, drying temperature, and cutting accuracy, ensuring consistent and uniform filter papers. Moreover, automation reduces the reliance on manual labor, minimizing errors and improving overall efficiency. Manufacturers are continually investing in advanced automation technologies to streamline their production processes.

Regulations and Standards

Efficient cigarette filter paper production is subject to strict regulations and standards to ensure consumer safety. Regulatory bodies set guidelines regarding the maximum levels of harmful substances, such as tar and nicotine, that can be present in cigarette smoke. Manufacturers must comply with these regulations, and their filter papers are regularly tested to ensure they meet the required standards. Compliance with regulations not only guarantees consumer safety but also fosters trust in the industry.

The Future of Efficient Cigarette Filter Paper Production

The future of efficient cigarette filter paper production lies in continuous innovation and sustainability. Manufacturers will continue to invest in research and development to improve the efficiency and effectiveness of filter papers. Additionally, sustainability initiatives will gain further prominence, with a focus on reducing waste, improving energy efficiency, and exploring alternative raw materials. By embracing these advancements, the tobacco industry can contribute to a healthier and more sustainable future.