The Importance of Cigarette packaging plate roller specifications

When it comes to the production of cigarette packaging, one crucial component is the plate roller. As the name suggests, the plate roller is responsible for creating the necessary patterns and designs on the packaging plates. In this article, we will explore the specifications of cigarette packaging plate rollers, shedding light on their importance and the key factors to consider while selecting one.

1. Understanding Cigarette Packaging Plate Rollers

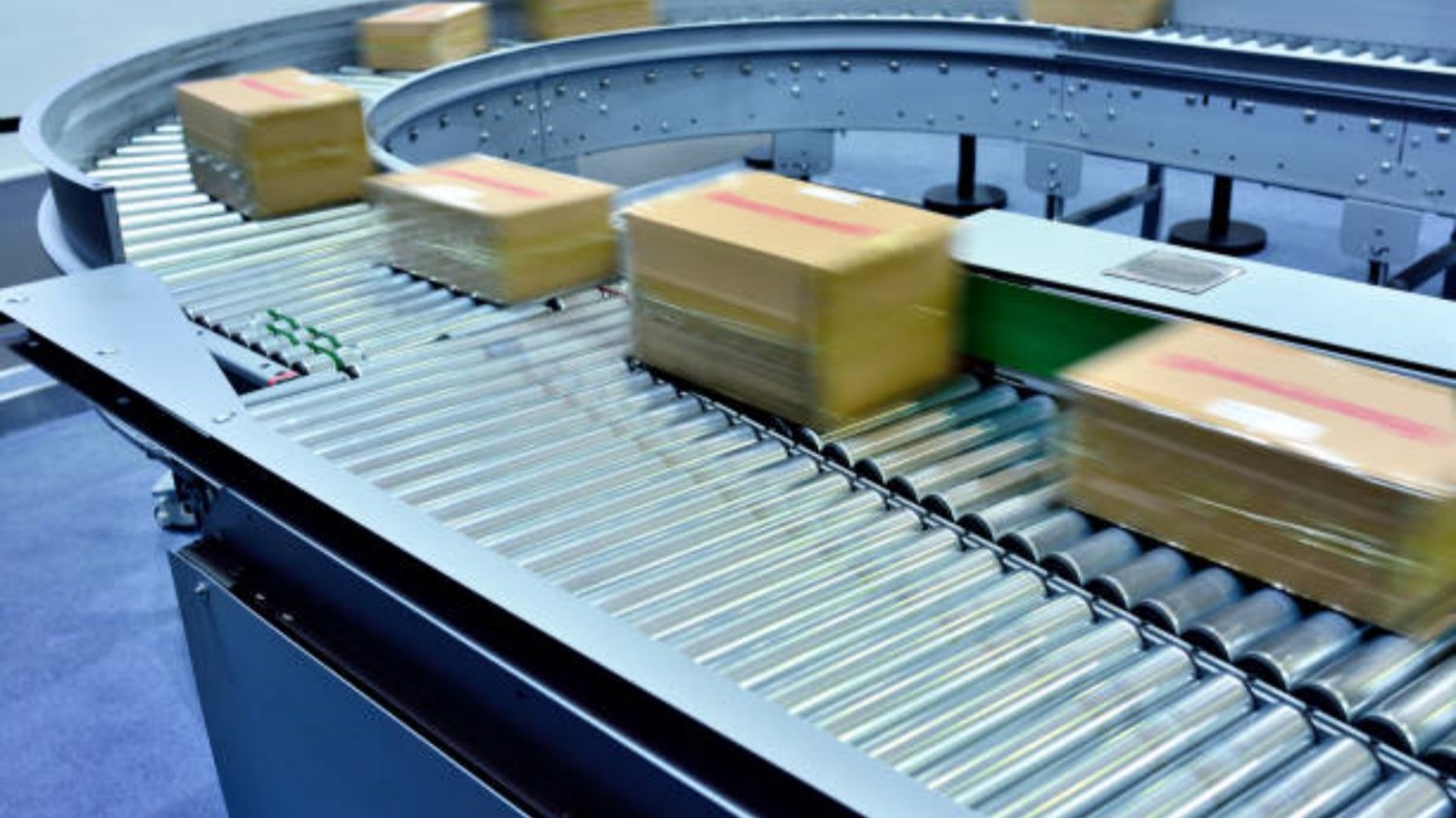

Cigarette packaging plate rollers are specialized machines used in the printing industry. They are designed to create the intricate patterns and designs that give cigarette packages their unique appearance. These rollers are responsible for transferring the design from the plate onto the packaging material, ensuring a consistent and high-quality result.

2. Roller Material and Surface Finish

One of the critical aspects of cigarette packaging plate rollers is the material used in their construction. Typically, these rollers are made from high-quality metals such as steel or aluminum. The surface finish of the roller also plays a crucial role in determining the quality of the printed design. A smooth and even surface finish ensures better ink transfer and consistent patterns.

3. Roller Diameter and Width of Cigarette packaging plate roller

The diameter and width of the cigarette packaging plate roller are essential specifications to consider. The diameter determines the circumference of the roller, which affects the speed and accuracy of the printing process. The width of the roller determines the maximum size of the packaging plates that can be used. It is crucial to select a roller with the appropriate diameter and width to meet the specific requirements of your production line.

4. Engraving Depth and Pattern Accuracy

The engraving depth of the cigarette packaging plate roller is another critical specification to consider. The depth directly affects the quality and visibility of the printed design. A deeper engraving allows for bolder and more defined patterns, while a shallower engraving may result in a less pronounced design. Pattern accuracy is also important, ensuring that the roller can reproduce the desired design with precision.

5. Speed and Efficiency of Cigarette packaging plate roller

In the fast-paced world of cigarette packaging production, speed and efficiency are crucial factors. The speed of the plate roller determines the production rate, while efficiency ensures minimal downtime and optimal use of resources. When selecting a cigarette packaging plate roller, it is important to consider its speed and efficiency specifications to ensure smooth and uninterrupted production.

6. Roller Maintenance and Longevity of Cigarette packaging plate roller

Like any other machinery, cigarette packaging plate rollers require regular maintenance to ensure their longevity and optimal performance. It is important to choose a roller that is easy to clean and maintain. Additionally, selecting a roller made from durable materials can contribute to its longevity, reducing the need for frequent replacements.

7. Compatibility with Packaging Materials

Cigarette packaging can be made from various materials, including paper, cardboard, and foils. It is crucial to ensure that the selected plate roller is compatible with the specific packaging material used in your production line. Compatibility issues can lead to poor ink transfer, smudging, or other printing defects that affect the overall quality of the packaging.

8. Customization Options for Cigarette packaging plate roller

In the highly competitive cigarette industry, customization is key to standing out from the crowd. Some cigarette packaging plate rollers offer customization options, allowing you to create unique patterns and designs for your packaging. Considering the customization options available with a plate roller can give your brand a competitive edge.

9. Safety Features

Ensuring the safety of workers is of utmost importance in any production environment. When selecting a cigarette packaging plate roller, it is important to consider the safety features it offers. This may include features such as emergency stop buttons, safety guards, and protective covers to prevent accidents and injuries.

10. Cost and Return on Investment

Lastly, the cost of the cigarette packaging plate roller and its return on investment should be carefully evaluated. While it may be tempting to opt for a cheaper option, it is important to consider the long-term benefits and potential savings that a higher-quality roller can offer. Investing in a reliable and efficient plate roller can ultimately result in higher productivity and cost savings in the long run.